Turning Miss Piggy into Sizza Lean

Before we start, click on over to the STORE and grab yourself a rad Apex Attack hat, or some awesome stickers. Help support this page! Thanks a bunch.

The great Colin Chapman was once asked about the midset of building a Lotus car. His answer? “Simplify, then add lightness”

As a fan of MR2s, you’re obviously aware of Lotus cars. Same basic MR platform, and most Lotus cars use Toyota power plants. Hell, the Evora uses a 2gr.

One thing I’m always asked about my car is “I bet that thing is real light, like 2000 pounds?” Well. No. The first and third gen are indeed very light cars from the factory, but the SW20 was a bit of a pig. A loaded Turbo came in at about 2800-2900 pounds. Oink Oink.

Since I’ve simplified the car in terms of engine (yes I think a NA V6 is simpler than a turbo 4 cylinder), it was time to get serious about weight loss. Over the years of building this car, I have done my best to lighten things wherever possible. Last year I bought a cheap mailing scale so I could really nerd out.

As I pulled things off the car, I’ve weighed damn near everything.

The infamous Jekyl and Hyde MR2 site has a decent weight list of stuff most have used as guidance. Some stuff is accurate, some is not.

http://www.jekylhyderacing.com/weight.htm

Last summer I was finally able to get my car on some corner scales and get a real accurate weight (vs the weigh station at the dump I used before).

This was with the car in full “Qualifying” spec. Passenger seat was out, track exhaust installed instead of my Berk. Gas tank was under 1/4, and 160 pounds of weight in the front seat (my weight) to help corner weight accurately.

With that, we can defer the car weighs right at 2500 in that trim. And about 2560 pounds with seat and exhaust back in.

You may be saying to yourself, “Mike, with all that carbon fiber and junk on your car, it’s still that heavy?”

Well, yes. I’ve taken lots of weight out of the car, but also added some, in the name of looking good. Huge wheels, body kit, flares, rollbar, and aero are all added weight. The 2gr is pretty much a wash in weight with an intercooled 3sgte. I’ve obviously removed all the obvious stuff like A/C, spare tire, stereo, etc.

Since I’ve been weighing things… here’s my list (subject to updates and changes!):

Single DIN Stereo and front door speakers (Rest of the premium audio system was removed years ago) - 5lb 14oz

Rear bumper support - 13 lb

Rear swaybar and brackets - 7lb 10oz

Subwoofer box lids - 2lb 7oz (pair)

Floor carpet - 4lb 13oz

Glass T-Top - 9lb 15oz (each)

Carbon T-Top (unknown brand) - 9lb 8oz (each) (Yes, my fancy t tops only save me a pound lol)

Driver Door Card - 7lb 7oz

Pass Door Card - 7lb

1 Radiator Fan (ebay brand) - 2lb 4oz

Berk muffler Section - 29lb 6oz

DIY “Track” exhaust muffler - 8lb 10oz

DIY Fiberglas Splitter with all hardware and air dam - 22lb 2oz

OEM Armrest - 2lb 15oz

Passenger Seat with slider/bracket - 39lb!

So, we’re entering the land of diminishing returns here. More effort (or cost) for less weight saved. I am admittedly very scared of cutting up my wiring harness, so I’m leaving that alone. I know there’s probably 10+ pounds to be found in wiring… but it just intimidates me too much. I may remove one harness and find out it is needed to power something necessary. Yes, a carbon trunk lid would really save some weight… but that opens up a pandora’s box with figuring out a wing mount solution that’s strong enough (Chinese carbon ain’t that strong), likely leading to a new wing entirely. You see how I’ve thought most of this through?

Unfortunately the front of the car is the easiest to shave weight. Let’s start there!

The OEM battery is a behemoth. I never weighed it when I had it, but I’ve seen a few places where its a 35-55 pounds. Yikes. The go-to lightweight battery is an Odessey PC680. They’re only about $100, and are a serious savings at 14lb 5oz. The big drawback is they don’t last very long, typically about 2 years.

I got about that out of mine, at the autocross I ran the battery gave up the ghost when leaving the venue. I even had to get gas with the car running because I had no way to jump it if I turned it off.

Enter a real contender… Antigravity! Amir at RS Future hooked me up with a badass unit. It’s made for ATVs but has enough juice to fire up the 2gr. It’s stupid light. When I got the package in the mail I thought it was empty.

Seriously, 3 lb!

The other amazing feature is the restart button. The battery is smart, it will realize when there is a draw on it and effectively disconnect itself when it is low on power. So, you will try to start the car, realize it’s dead, hit the restart button on it, and voila, it’ll have enough juice to fire up the car and then that alternator will recharge it. Technology is amazing. That was an easy 11lb.

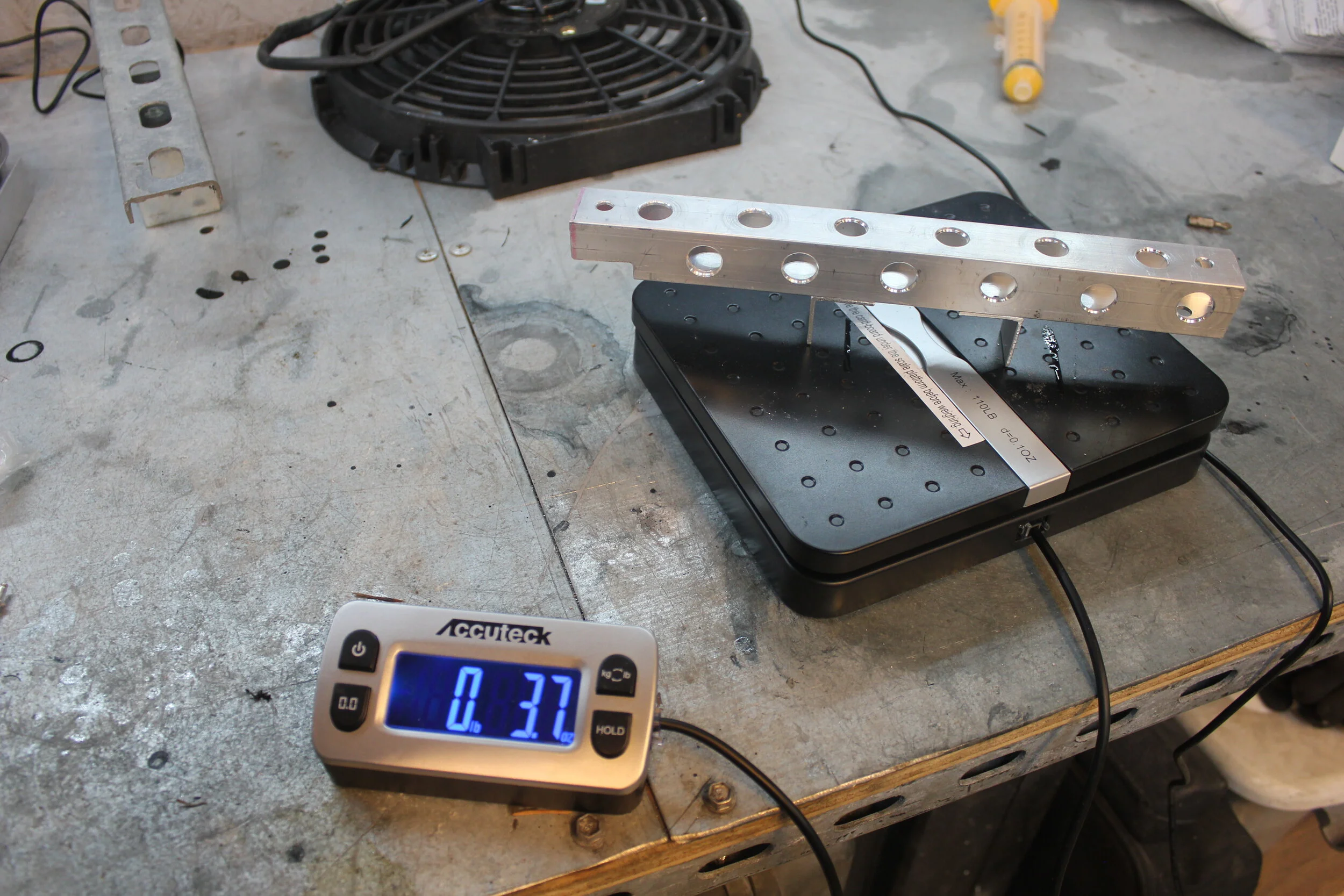

On the left is a crude battery tie down I made for the Odessey. For the AntiGravity I saved another pound by using an aluminum square stock and aluminum angle brackets. Material choice is key.

Here’s another one. The MR2 starter is also heavy. The one that comes from 2gr powered cars is smaller, and lighter.

Almost 4 pounds! And these things are cheap on ebay. This was about $35 shipped, genuine Toyota starter. You do need to put a different connector on the signal wire for the solenoid, but that’s an easy crimp. Note I cleaned it up before install.

It bolts right into the oem location. Very easy 1 beer mod.

While I like the look of my solid aluminum wing uprights, they’re so thick (3/8”) they could easily handle the load on them with less material. So, time to hollow them out a bit.

With a lot patience, a jigsaw, carbide tip on a rotary, we were a bit lighter. 1lb 8 oz to be exact.

Here’s what the airfoil on my wing weighs in at. 11 pounds give or so. We’re keeping that obviously.

This big ass master cylinder brace came with the car when I got it. I think is ETS brand… which is no more. One thing is for sure, it’s very stout. It’s also heavy for what it is… about 2 pounds.

Together with my homemade frunk duct, it’s really not that bad. But, it could be lighter. And it definitely could function better. I have plans to build a much less crude version of this soon, hopefully before spring. Check back on that.

Another heavy part of the car are the front and rear bumper supports. They’re made out of fiberglas and steel. I wouldn’t remove these if your car sees the street often. Yes mine does see the street, but not much these days to be honest.

DISCLAIMER: Removing safety equipment can be dangerous! Do so at your own risk, in Mexico, on a closed course.

I removed the rear one last year. With an entire engine, two firewalls, and lots of other stuff between me and the rear bumper support, I felt ok removing it. Plus, it’s super simple to remove, and you just build some very simple brackets to help the bumper cover keep its rigidity. 13 pounds saved there, right where it’s needed most, the rear of the car.

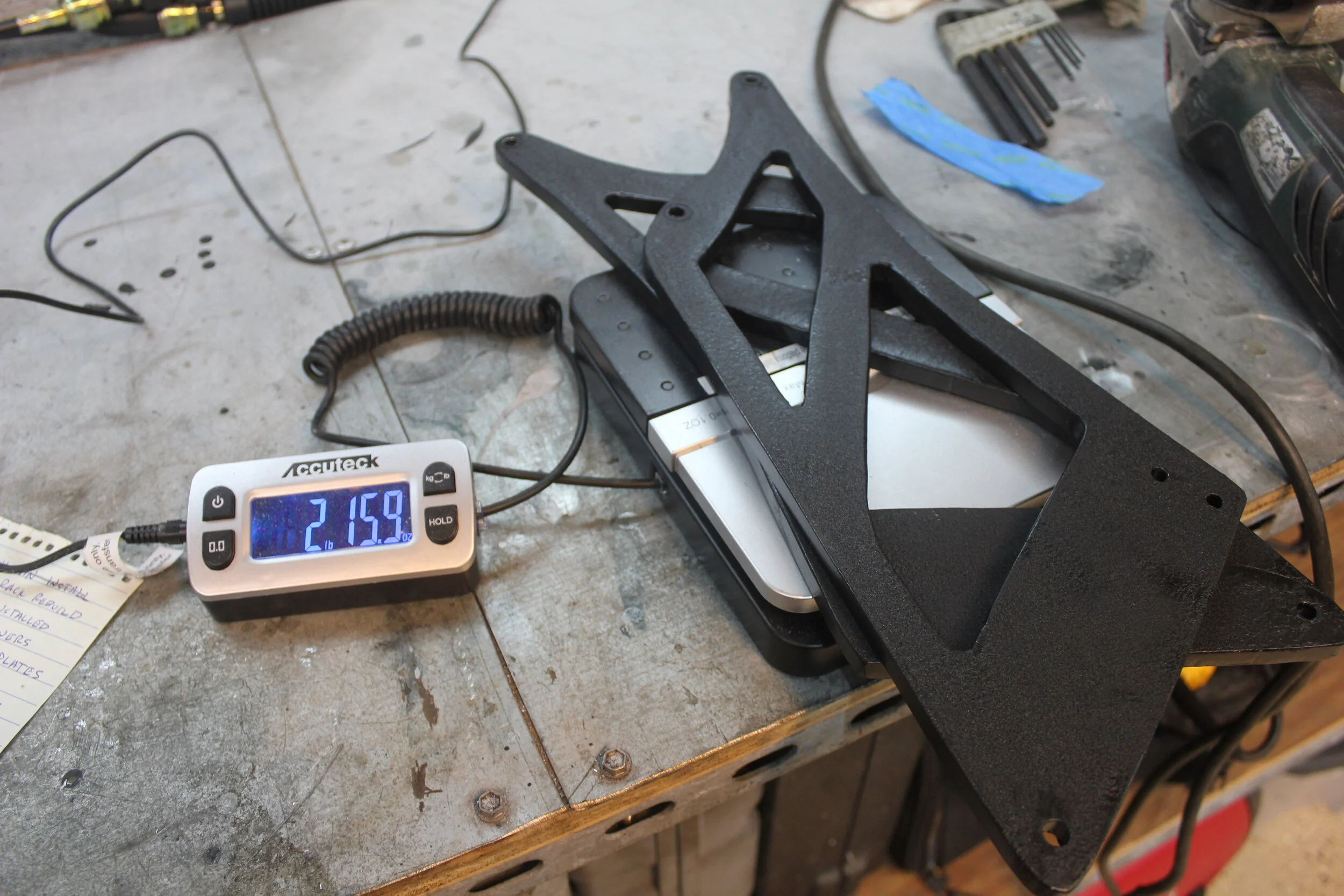

The front support is a different beast. It has mounts for the tow hook (needed for track events), splitter rods, fog light mounts, and it actually provides a lot of support for the bumper cover. So we would need to fabricate something here to hold the front end together.

16 1/2 pounds! Damn girl! We can do better than that.

First, we save the mount brackets off the OEM support. Easy enough to cut away the stitch welds and clean up.

I’ll take any chance I can to use my tubing notcher. One of those rarely used tools, but worth it when you need it.

Using an electricians tube bender, I was able to slightly bend the ends of the tubing to match the oem curve of the support.

Now I tacked it up for a test fit.

Dang! Looks about perfect. That was almost too easy.

Here’s the initial tack up.

I boxed in the drivers side mount. I will be adding a tow hook here, so I wanted it strong enough to pull the entire car if need be. Here it is tacked up.

Yes I still want to keep my foglights. I use them as daytime driving lights to give my car a bit more visibility to other cars on the road. So we need to build some mounts for the lights. Cardboard to the rescue.

If you have a half-circle on a fab piece, drill the full circle first and then cut the remaining piece out.

Tacked in. Welds look like boogers, but are pretty good honestly. The slag makes them look worse than they are. We also added some rivnuts where the actual fog lights will bolt in.

Also added some proper mounting points for my splitter rods.

My tow hook showed up, the hard part was going to be cutting the hole in the bumper.

Measure a bunch, then say a prayer and start cutting.

Perfect! See the bar behind the foam? The yellow dot is where we’ll weld the tow hook.

Overall, I’m happy with the fit and finish. Now to paint it flat black so the camera can’t see any detail.

Perfect!

The best part, it’s over 12 pounds lighter! Would it hold up the same in a crash? No… but I’m relying on my other safety equipment there. Along with the rest of the chassis crumple zones.

If you start snooping around, you can always find some weight. Here I spent some time one night trimming some brackets, and found some hardware no longer holding anything. The result… half a pound. Do that 200 times and you saved 100 pounds!

Next, is a system I’ve come to rely on, but think I’m ready to remove. ABS. Since I’ve gone to the Raybestos race pads, I’ve felt the ABS has hindered more than helped. It is an antiquated system, designed in the 80s. So, let’s try without.

I labeled things and figured out I really only needed to build one line and add a tee to the system when I removed the behemoth of an actuator.

Simple! Gave me an excuse to buy a brake flare tool too.

Line out of the Wilhelm bias valve goes to the rear brakes, and I added a tee for the fronts off the master cylinder.

With the actuator, ecu, and mount brackets, we got another 14lb 3oz pounds out! Don’t forget to bleed the brakes again.

On the interior, I removed some stuff I’m not sure I’ll miss. If I do, it can go back in.

Headliner, dome light - 2lb 2oz

Glovebox - 3lb 2oz

Passenger Oh Sh!t handle - 4 oz

And… the door cards. I like the mr2 doorcards a lot, but I was surprised when they weighed in at 7 lb 6 oz each.

I’ve always wanted to build some simple doorcards, why not try. Give my interior a bit more spartan feel.

If I went whole-hog racecar, I could really gut the door of the locks, actuators, and window equipment, likely saving 30 pounds per side. But, I like having power windows, and locks. No lexan, yet. I took off what I could, and re routed the wiring harness.

Using some scrap pipe, I screwed it to the edge of my workbench to help form a nice radius when we bend the door card.

I bought some larger sheets of HDPE 1/8” plastic. This stuff is light, rigid, and cheap. Each sheet was about $20. I use it all over on this car for general fabrication. One side is textured so it has a nice finished look.

I started the first one by cutting out the general shape of the door card. This was easy to figure out where the hole needed to be for the door latch.

Then, I put it on my improvised brake, and using a heat gun, slowly bent the top of the doorcard to fit nicely into the window threshold.

Well, that worked… but looks pretty crappy. It was tough to get absolute even pressure across the entire piece. I also didn’t have have enough material to grab onto since I cut the piece before bending, so let’s try this the other way around.

This time we’ll bend the entire sheet, then cut out the shape of the doorcard.

Much better. You need a ton of patience with the heat gun on a piece this big. I practiced on scrap a few times.

Ahhhh things are looking good, now to most difficult part, cutting the door latch hole in the correct spot. I measured a TON, and eventually got it pretty dang close. Start with a small hole and expand it to fit. You can take away material, but you can’t add it back on.

Now we need to find a good spot for the window controls. If you put it low enough there’s a good spot for it that avoids the window as it rolls down. It’s not the most ergonomical spot for the passenger, but it will rarely be used.

If you cut the holes out correctly, the controls snap in like OEM.

I used some cheap tow straps as door pulls. Mounted through the doorcards to the inner part of the door. Overall I love the look!

Onto the driver side door. The window/lock control panel is much bigger and deeper, so this one won’t be as simple.

I decided to try building a box for the controls. This will also serve as a simple elbow rest when highway driving.

That wasn’t too bad. With some aluminum angle and rivets it’ll look better and hold its shape.

I didn’t take as many progress pics of this side, but the finished product turned out great. The top is aluminum angle that is riveted on and fits into the OEM window threshold.

Add a tow strap as a pull. Done. Final weight, 4lb 1 oz for passenger, 4lb 15oz for driver. Total savings, 6lb 2oz (some plastic/wiring saved too). A lot of work for what it is, but a project I’ve wanted to try for a long time. I like the look of them, and can always go back to OEM if I want.

Onto another project I’ve wanted to tackle. The OEM tilt. It’s an over-engineered, heavy monster. Holy cow is it big and heavy. Full of springs, levers, doohickeys, and whatchmacallits.

Stephen Godfrey has a badass Australian 2gr race sw20. And he turned me onto trying the column from a Toyota Echo.

I went to a local Pick-N-Pull. $30 later I had one in hand. It was significantly simpler design, and only 5 pounds. Over the next few nights I spent a lot of time welding and building brackets with several different variations. It snowballed from a simple adaptor bracket, to welding directly onto the column to make it fit with a decent driving position. In the end, it all looked like it was going to work out and save another 7-ish pounds.

But, upon final install, the blinker assembly inner diameter was smaller than the Echo column outer diameter. This is important. It controls the blinker shut off, and the steering sensor.

From my understanding, the OEM power steering system will turn itself off to preserve pump life when the car sits at idle for more than 20-30 seconds (like a long stop light, or in traffic). When the car gets going again or there it a steering input, the pump turns back on to give assist. Without this sensor, I presume the power steering would fail safe off. Since I can’t really modify the plastic sensor to fit over the steel column, I unfortunately had to abandon this project. With my head held low, in went the OEM column again. When doing mods like this, it’s important to not burn bridges on parts…. so you can go back to OEM if need be. I try to be calculated with this kind of stuff.

They make all sorts of DIY lightweight steering column kits. But, they’re all around $200+. $200 to save a realistic 7-ish pounds could be better spent elsewhere on the car, so for now I will run the OEM tilt column again. Bit of a bummer, but this was uncharted waters for a street/track car. I want to have power steering and functional blinkers. Luckily it only cost me about $30 to figure out.

So far this winter, the total weights saved:

New Battery and tie down - 12lb 5oz

Wing Uprights - 1lb 8oz

Headliner/Oh Sh!t handle - 2lb 6oz

2GR starter - 3lb 12oz

Glovebox - 3lb 2oz

Front Crash Bar - 12lb 1oz

ABS actuator/ECU - 14lb 3oz

Doorcards - 6lb 2oz

New helmet - 7oz lighter

Random brackets trimmed/hardware - 3lb 4oz

That’s a total of 59lb 2oz! Many people will scoff at saving small ounces here and there (lots of keyboard warriors have told me it’s not worth it), but 59 pounds out of the car is 3/4 of a tank of gas weight. That’s significant. A lot of it was free or very cheap as well. I would’ve loved to get a solid 100 pounds out of the car, but now she’ll squat at well under 2500 pounds. 2600 or so with me in it.

Power to weight ratio is estimated at 6.68 pounds to horsepower. A Porsche 911 GT3 is 6.06. We’re closing that gap!

Do I have more weight I can get out of the car. Absolutely. But it’s starting to come at a high cost/effort. Some ideas:

Carbon trunk lid - opens a big can of worms. I would need to reconfigure my entire rear wing to chassis mount on the rear quarter panels. Not trusting a chinese carbon fiber part for real aero load.

Remove all the underbody weather proofing, likely a substantial gain… but man does that sound miserable with a grinder disc.

Remove remaining sound deadening inside - 90% of it is gone, the remaining is probably a few pounds, but again, makes a huge mess.

Remove parking brake - probably 10 pounds worth, but I use it a lot.

1 wiper setup - minimal gains, but it’d look very race car.

Replace rear quarter windows and rear glass with poly/lexan - quite a project with a rollbar installed, save estimated 7-ish pounds.

Flush mount headlights - substantial gains (10+ pounds), but the only kit I like is pricey.

Remove entire interior - minimal gains, the plastics are light.

Start replacing bolts with lighter material - minimal gains, substantial cost (titanium ain’t cheap)

So, if you have any amazing ideas of stuff I’m missing please let me know! We’re also getting down to the wire for testing and GTA which is VERY early this spring. So I’ve shifted focus on more important parts of the car, like a new LSD! More on that soon.