Break, Bleed, Brake, Repeat

Remember when I said I wanted to give you guys smaller, more bite size content updates? Well, here you go!

The SW20 chassis has a few design flaws. It's not the most epic supercar ever built. It wasn't designed with a double wishbone suspension, aluminum frame, or t-tops that seal out the weather. But it also has a lot of awesome features of the chassis that we adore; potent turbo motor, LSD transmission, MR layout, and t-tops that leak.

One of the inherent design pros with a mid-engine layout is they're easy on brakes. With most of the weight over the rear axle, the front brakes don't have to work as hard as a typical FF or FR car. The best evolution of those brakes were the 1993+ turbo cars. Larger two piston front calipers with bigger rotors and a bracket on the rears to move the rear caliper further out on another larger rotor to gain more braking leverage. It all added up to an impressive braking force.

Most occasional track guys like myself get themselves a 93+ setup, Porterfield pads, some good fluid, and beat the hell out of the brakes. Cases of brake fade on this this setup during a 20-30 minute lapping session are very few and far between. I'll admit, I never have experienced any fading with the 93+ setup on my old car, or this one.

Really the only drawback to the 93+ setup is unsprung weight. I wouldn't be surprised if the full 93+ braking system (calipers, brackets, rotors) is 100+ pounds. That, and the rear calipers are becoming impossible to come by, nation-wide auto parts stores have been out of stock for the last 4 years.

As we all know, big brake kits are friggin cool. They just are. I want one. A lot of guys go out there and slap on some huge front kit and call it a day. That's no bueno, as it screws up your braking bias big time. Other guys will fit brakes from a FR car, like 300zx, which again, will screw up your brake bias big time.

Luckily, I know a guy. Alex Wilhelm. Track day guru, and MR2 nerd. He sees a need for an aftermarket part, researches it til the cows come home, and then goes and builds it. You saw my Suspension Geometry Kit I installed last fall, now let's check out his Big Brake Kit. It was designed and built to keep the OEM brake bias as close as possible, uses cheap rotors (for 2 piece anyway), and saves a whopping 25 pounds over the 93+ brakes!

The cool thing about Alex's kit is, he just sells the proprietary parts of the kit, allowing you to go buy the off the shelf parts as you can afford it. I actually bought his kit last year, and have been slowly chipping away at purchasing the calipers, rotors, and pads since. He uses all Wilwood calipers, they're easy to come buy, affordable, and rebuildable. Now that I finally got everything, let's get out there and turn a wrench.

Here's the full kit! Well, minus the parking brake calipers (they were in the mail at the time of this picture), and the rotors are already put together. But yeah, the picture at least looks cool eh? When you first get the kit, you will need to build the rotors. So let's start with that.

The Wilhelm kit doesn't have the absolute biggest rotors out there. There's a few kits running Supra TT rotors, which are a bit bigger... but MUCH heavier. The 2-piece design is light, and uses a short track style rotor, which is cheap.

It's helpful to turn on Spice Girls - "When 2 Become 1" while building these.

Bolt them up, torque to spec. Simple right? Nope, these need safety wire. You DO NOT want your rotor coming apart at 130mph. So, get on Amazon, buy some safety wire pliers, open youtube, and get learnin!

After about half an hour, I had finished one whole rotor! They didn't look that good either. Just like anything in life, the more you do, the better you get. The last rotor only took about 15 minutes, and looked much better, so I went ahead and re-did the 1st rotor. I know it's probably overkill, but I had the wire, why not make sure it's 100%?

Now that we have a new life skill, let's forget about it for a few years. Get the car on jackstands and pull the old brakes.

Old and new front rotors, less weight, much larger.

The big brake kit got no time for OEM dust shields. In case you didn't know, to remove the dust shields in tact, you have to remove the hub, press out the bearing, and then press out shield (or something stupid like that). That is dumb, so I cut them off.

New and old fronts. Now the size difference is becoming more apparent.

While I had the old brakes out, I needed to make things more complicated. So, I scrubbed the crap out of the wheel wells, and prepped them for a re-coat of underbody coating. Pro Tip: Wrap things you don't want to paint, or burritos, in aluminum foil.

After the underbody coat dried, I also sprayed the wheel well with satin black paint. This will make the wheel wells much easier to hose off in the future. Apologies for the terrible pictures, I was high on spraypaint fumes.

Following the Wilhelm Kit instructions, I started with the fronts. Bracket installed. Fitment felt like OEM.

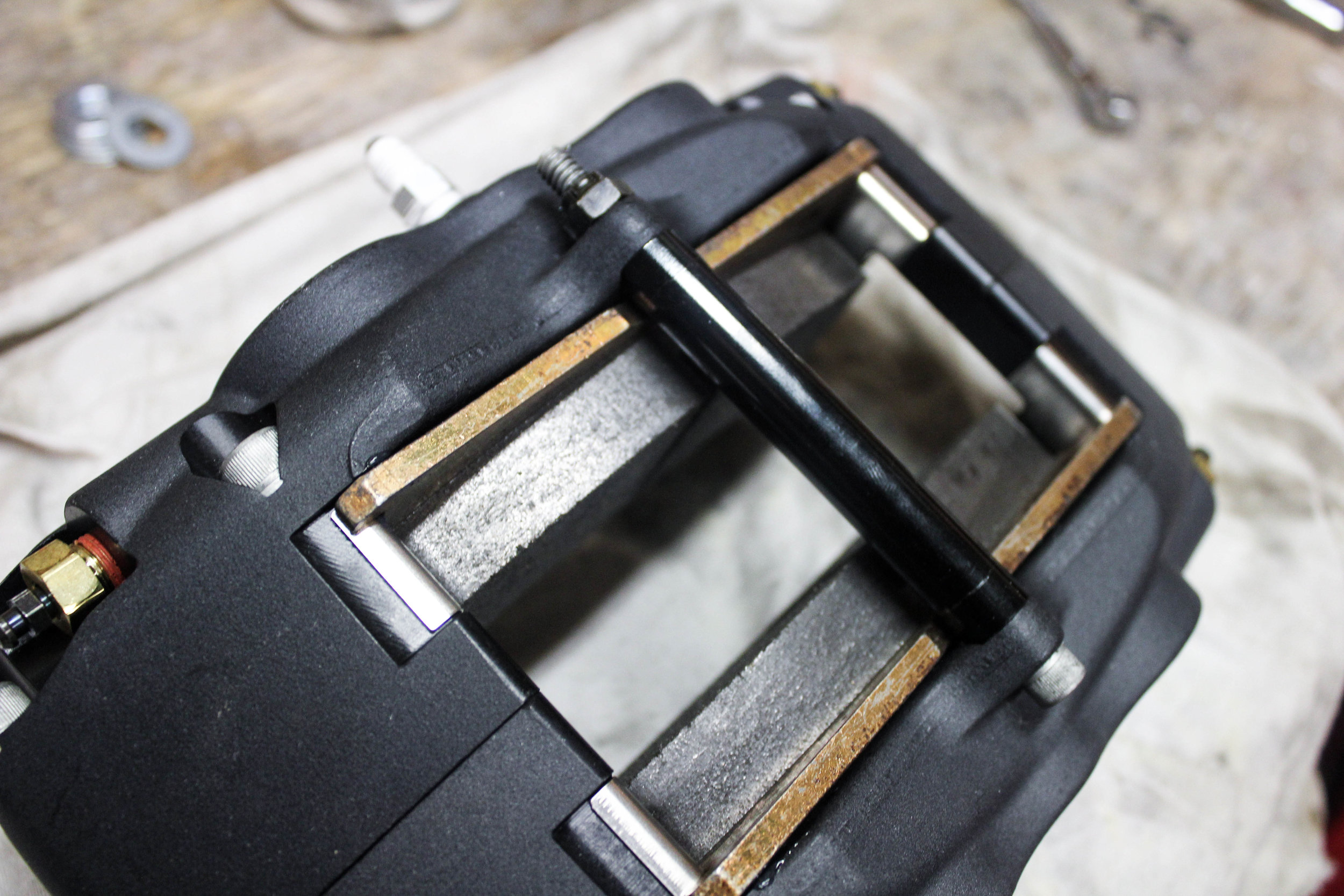

Pads installed in the calipers. Wilwood made this EASY. You could change all 8 pads in about 5 minutes. You just pull that center pin, and the pads come right out. I used some caliper grease on the backside of the pads to hopefully deter any squealing. I'm running the BP-20 pads as my first set. Basically the Wilwood track day pad, but doesn't need much heat to be effective, so totally streetable. I found out later Porterfield makes their pads for Wilwood calipers, so I hope to try those next.

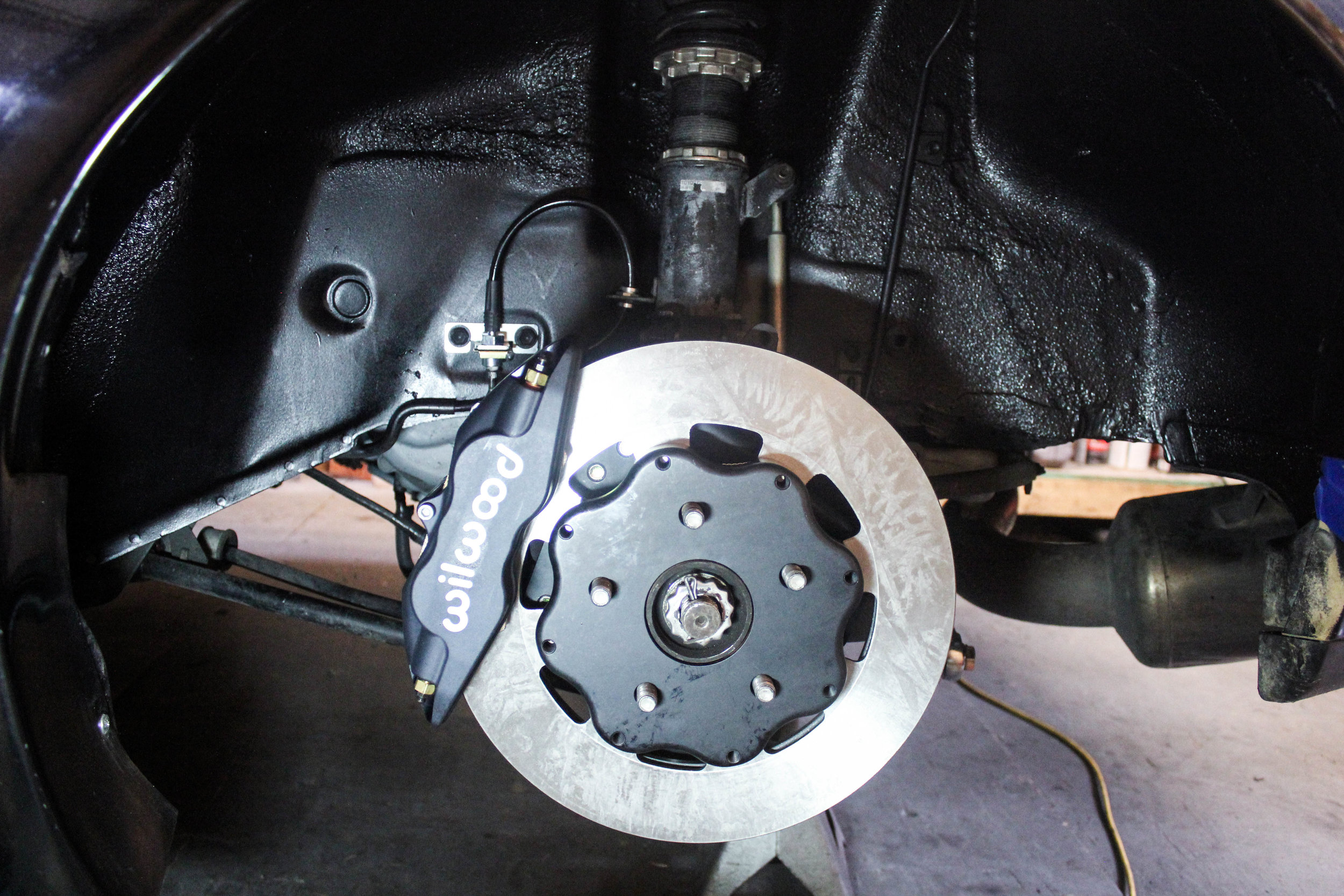

Rotors and calipers installed! The Wilhelm kit also includes new stainless brake lines. Those are installed now too. Overall everything fit great, it was refreshing to install an aftermarket part that fit like OEM. Make sure you use a little blue locktite and torque to spec.

The rear wheel wells were nasty. Remember the cars' historic baja past? Yeah, it shows here too. Probably removed 3 pounds of dirt in each well. You also can see my filler panels welded in, they were just primed at this point, so they needed to be coated with something tougher.

Cleaned and prepped.

Ahhhhh, fresh.

Rear brackets bolted in. Again, great fitment. The larger bracket is for the E-brake, and bolts to the hub via your old dust shield mounting points. Nice ingenuity here, Alex.

Rear calipers in! At this point my E-brake calipers were still a few days from showing up. So I decided to bleed the brakes and try them out. After 15 minutes of pleading, my ever eye-rolling wife came out to the garage to pump the brake pedal while I bled the calipers, starting furthest from master cylinder and working my way towards it. I use ATE TYP 200, haven't had any fading yet.

Behind my LM's, the brakes are a sneaky add on. They definitely don't pop out at you like most big brake kits, but I like the subtly.

A few days later, the E-brake calipers showed up.

Let's pop them on.

Again, OEM like fitment. Bolts right in. The Wilhelm kit also comes with new parking brake cables which need to be installed.

The new Wilhelm cables on the left, old OEM cables on the right. I know I'm beating a dead horse, but the quality is legit! I'm sure these cables will last just as long as OEM, if not longer.

Cable routing under the car. You can see my new seat and belt mounting plates now welded to the floor. Voila, new brakes in! Overall this was a pretty easy modification. You could bang it out in a Saturday as long as you had all the parts. Pulling the old crusty brakes takes probably twice as long as putting the new ones in.

Now before we go for a big ol romp on these new brakes, I had a few other interior chores to take care of. When I bought the car, the previous owner had installed some legit instrumentation, AEM TruBoost and Wideband. The owner had installed them professionally, with an ashtray gauge pod too. I thought the ashtray pod would be an upgrade over the fastNfurious a-pillar pod on my old car. But after driving the car all last summer, the ashtray pod just wasn't practical. When doing a WOT pull, looking down to the pod was pretty dangerous, and was tough to read. So, back to the a-pillar pod we go!

I actually traded the ashtray pod to the guy who bought my a-pillar pod a while ago, thanks Duncan.

Interior torn apart. Running both wiring harnesses up through the dash and to the a-pillar.

Excess wiring looped up and zip tied away.

An hour later, the gauges were up and running. But we still had one more chore.

This car is becoming a rather large investment. Cars, especially track cars, are subject to intense heat and stress. Sometimes, they like to catch on fire. This $25 extinguisher is rated for electrical and gas fires, basically automotive use. It'll be nice to have on board, and gives me hella 2000s fastNfurious points.

After some research, I obviously wanted it within easy reach. The best place seems to be right under the passenger seat. When you move the seat to a regular position, the extinguisher is hidden. I can easily unlatch it in 5 seconds. Nevermind the nasty floor, 6 months of sanding dust caught up to me.

Now our chores are done, lets go for a quick cruise!

I have lots of quick little cruises around my area. Easy to drive out, test the car, and see what changes need to be made. Or just take in the last 6 months of work.

Diggin the brakes filling up the space behind the wheels.

Still have more plans for the rear.

So far, the brakes feel great, crisp engagement, great bite. I obviously haven't gotten to truly put some heat through them yet, but will give an unabashed review once I can. Ok, that's it for now, let's get this crap painted! Track day in a month, crunch time!